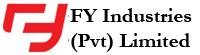

Round Steel Bar

We widely provide all kinds of hot rolled carbon steel and alloy steel with the process of hot rolling and continuous casting. Currently available diameter: 6mm-600mm. Length is customize. The material is focus on high carbon steel like S35C\S45C\S55C alloy round steel like 42CrMo\35CrMo. Mainly for hardware, machinery, automobile and ships manufacturing industry (providing certificate of classification societies).

Other grade steel as follow:

20Cr、40Cr、15CrMo、20CrMo、35CrMo、40CrMo、42CrMo、40CrNiMo、28SiMnVB、30SiMnVB、30MnCrB5、SCM415、SCM420、SCM420、SCM440、20CrNiMo、40CrNiMo、SNCM220、SNCM439、SCr420、SCr440、20X、40X、45X、SAE5120、SAE5140、SAE5145、SCr445、12XM、15XM、20XM、30XM、35XM、38XM、SCM430、SCM435、SAE4118、SAE4130、SAE4135、SAE4140、38CrMoAl、SACM645、E7140、Y12Pb、AC14、SUM22L、SUM24L、12L14、20Cr4、17Cr13-1.7016、41Cr4、15XM、13CrMo44、18CrMo4、25CrMo4、34CrMo4、34CrMo4、41CrAlMo74、20CrMnTi

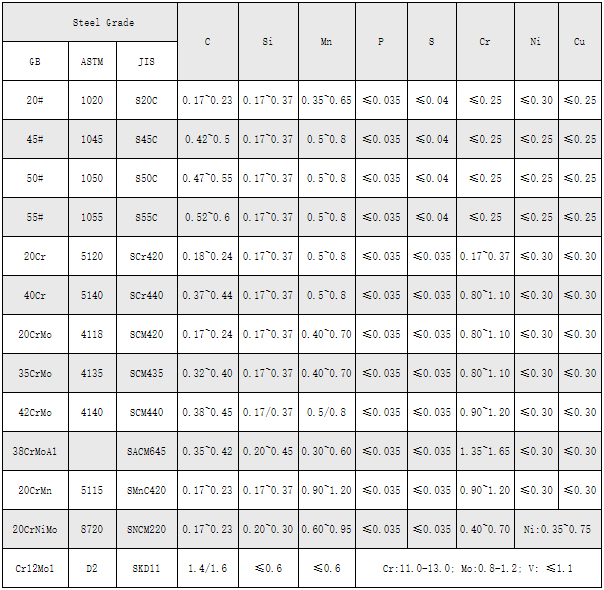

Grade Comparison And Chemical Composition

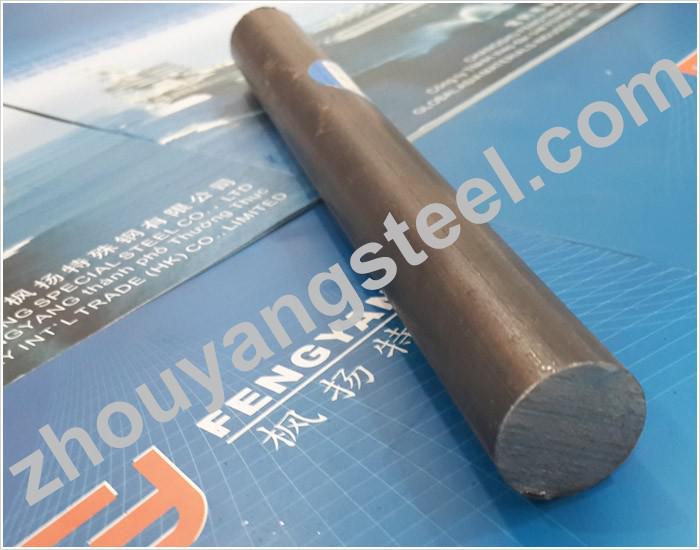

Forging is a process of using forging machines to pressure the steel billet and produce the plastic deformation to get the certain mechanical properties, shape and size. Forging and pressing are two main parts this process can eliminate the weakness of loose cast condition in smelting process and optimize the microstructure. Due to the process of forging saving the whole flow line, the properties of forgings are better than other products in same material. Most of the parts in high load and serious work condition are forgings. In general, the forgings are for transmission shaft or shaft under high torque and load like marine shafting (providing the certificate of classification societies).

Currently, the available size: 80mm-800mm. Main material:

20Cr、40Cr、15CrMo、20CrMo、35CrMo、40CrMo、42CrMo、40CrNiMo、28SiMnVB、30SiMnVB、30MnCrB5、SCM415、SCM420、SCM420、SCM440、20CrNiMo、40CrNiMo、SNCM220、SNCM439、SCr420、SCr440、20X、40X、45X、SAE5120、SAE5140、SAE5145、SCr445、12XM、15XM、20XM、30XM、35XM、38XM、SCM430、SCM435、SAE4118、SAE4130、SAE4135、SAE4140、38CrMoAl、SACM645、E7140、Y12Pb、AC14、SUM22L、SUM24L、12L14、20Cr4、17Cr13-1.7016、41Cr4、15XM、13CrMo44、18CrMo4、25CrMo4、34CrMo4、34CrMo4、41CrAlMo74、20CrMnTi