Other Products

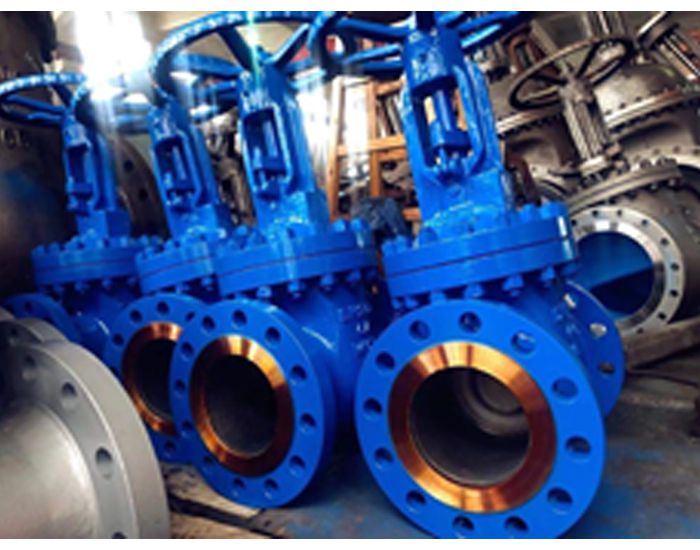

Valve

The company is involved JIS,ASTM,DIN,GB,EN and other standard, Materials include mainly HT200、HT250、QT400、QT450、WCA、WCB、WCC、CF3、CF8、CF3M、CF8M、1Cr5Mo、LCB、Stainless Steel and so on, Valves include butterfly valves, gate valves, ball valves, check valves, globe valves, 12 categories, more than 200 series, more than 4,000 specifications etc. Widely used in petroleum, petrochemical, chemical, electric power, metallurgy, water conservancy, medicine, municipal construction, water supply and drainage and other areas of the national economy.

Flanges

The flange is a part that connects the pipe to the pipe and is connected to the pipe end. There are holes in the flange, and the bolts make the two flanges tightly connected. The flanges are sealed with gaskets.

Our company can provides with the size is 1/2“~24",DN10~DN1000 and the pressure is 150LB~2500LB.Include butt welding, neck welding, thread, socket welding, blind plate, orifice flange, loose sleeve, long neck, 8 word blind plate. Materials include mainly HT200、HT250、QT400、QT450、WCA、WCB、WCC、CF3、CF8、CF3M、CF8M、1Cr5Mo、LCB、Stainless Steel , Involved HG20592-20626、GB/T9112-9113.4、Sh1406、JB/T74-86.2、ANSI B16.5、ANSI B16.47、ISO7005-1、API7S-15-93、DIN、JIS. Widely used in petroleum, petrochemical, chemical, electric power, metallurgy, water conservancy, medicine, municipal construction, water supply and drainage and other areas of the national economy.

Galvanized Steel Wire

Introduction

Our company providing main materials is in S45C , S50C ,S55C , S60C , S70C through drawing, then galvanized (Galvanized or hot-dip galvanized), Specification are 0.5mm~5.0mm Various specifications of galvanized steel wire can also be supplied to customers according to industry standards.

Application

Mainly used for planting greenhouses, farm, Cotton packaging, Metal mesh, Manufacture of steel wire rope strands for highway guardrail construction.

Physical Properties

Physical properties;Galvanized steel wire surface smoothing,Clean,No crack,Nod, thorn, scar and rust, uniform galvanized layer,Strong adhesion,Long lasting corrosion resistance,Excellent toughness and elasticity,Tensile strength should be 900Mpa-2200Mpa between.

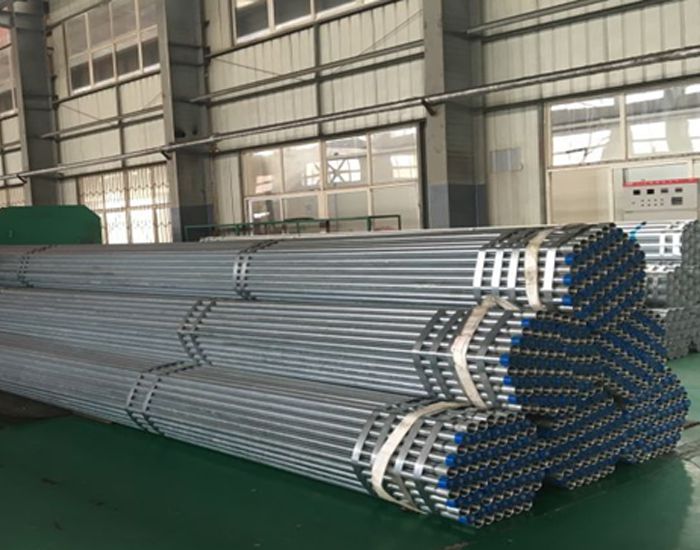

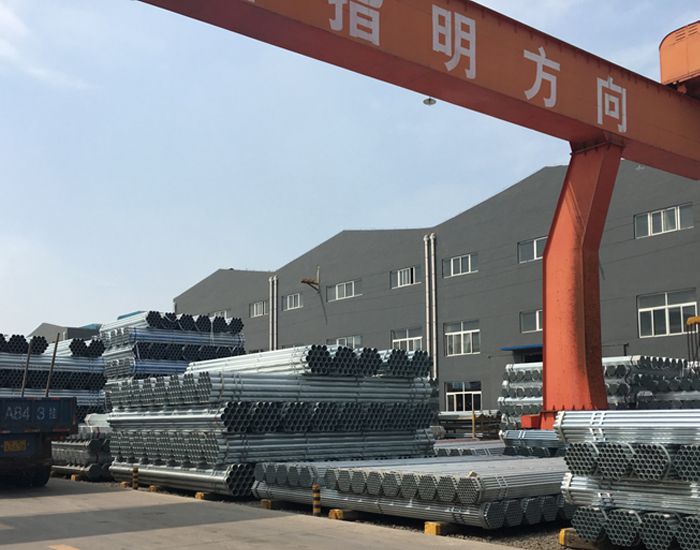

Galvanized Steel Pipes

Introduction

Galvanized steel pipe is divided into cold galvanized steel pipe, Hot dip galvanized steel, Hot-dip galvanized pipe is a reaction between molten metal and iron matrix to produce an alloy layer, Thereby combining the substrate and the plating. Hot-dip galvanizing is to pickle the steel pipe first, In order to remove iron oxide from the surface of the steel pipe, after pickling, Cleaning by ammonium chloride or zinc chloride aqueous solution or mixed aqueous solution of ammonium chloride and zinc chloride, Then sent to the hot dip plating tank, Hot-dip galvanizing has uniform plating, Strong adhesion, Long life and other advantages. Complex physics of hot-dip galvanized steel pipe base and molten plating solution, chemical reaction, Forming a corrosion-resistant structure with a tight zinc-iron alloy layer. Alloy layer and pure zinc layer, Steel pipe matrix is integrated, Therefore, its corrosion resistance is strong; Cold galvanized pipe is electrogalvanized, Very little galvanizing, only 10-50g/m2, Its corrosion resistance is much worse than that of hot-dip galvanized pipes. Regular galvanized pipe manufacturer, In order to ensure quality, Mostly do not use electro-galvanizing (cold plating). Only those scale small, Small equipment with outdated equipment using electro-galvanized, Of course, their prices are also relatively cheap. The Ministry of Construction has officially, Elimination of cold-galvanized pipes with backward, Do not use cold galvanized pipe for water, Gas pipe. Cold-galvanized steel pipe galvanized layer are, Zinc layer and steel pipe matrix are layered independently. Thin zinc layer, The zinc layer is simply attached to the steel pipe base, Easy to fall off. Therefore, its corrosion resistance is poor. In newly built houses, the use of cold-galvanized steel pipes as water supply pipes is prohibited.

Application

Hot dip galvanized steel pipe is widely used in construction, Machinery, coal, chemical, electric power, railway vehicles, automobile industry, roads, bridges, containers, sports facilities, agricultural machinery, petroleum machinery, Manufacturing industry such as prospecting machinery.

Material Use

Q195, Q235, Q345, SS400, SS33, HR2, St33, A3, 16Mn

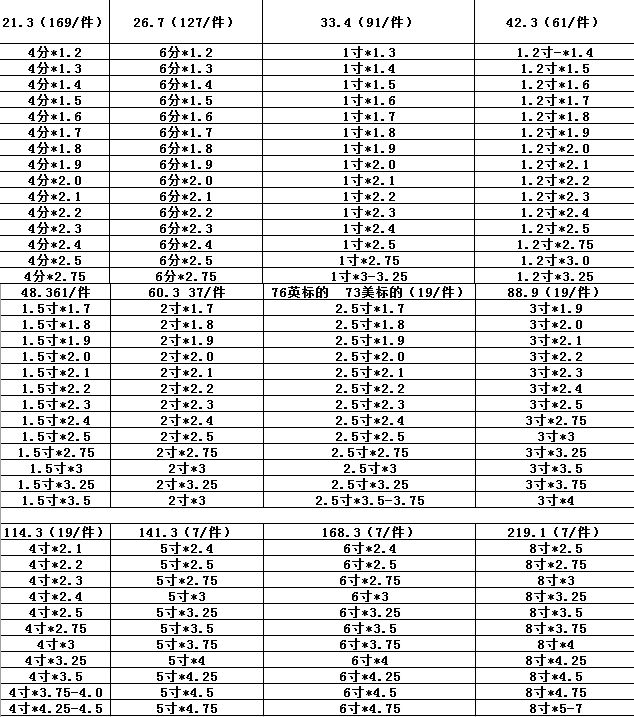

Production Size

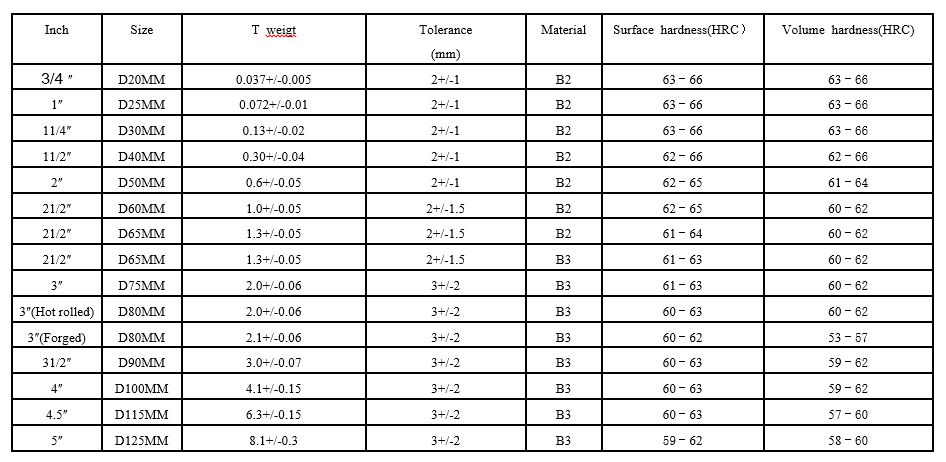

Wear Resistant Steel Balls

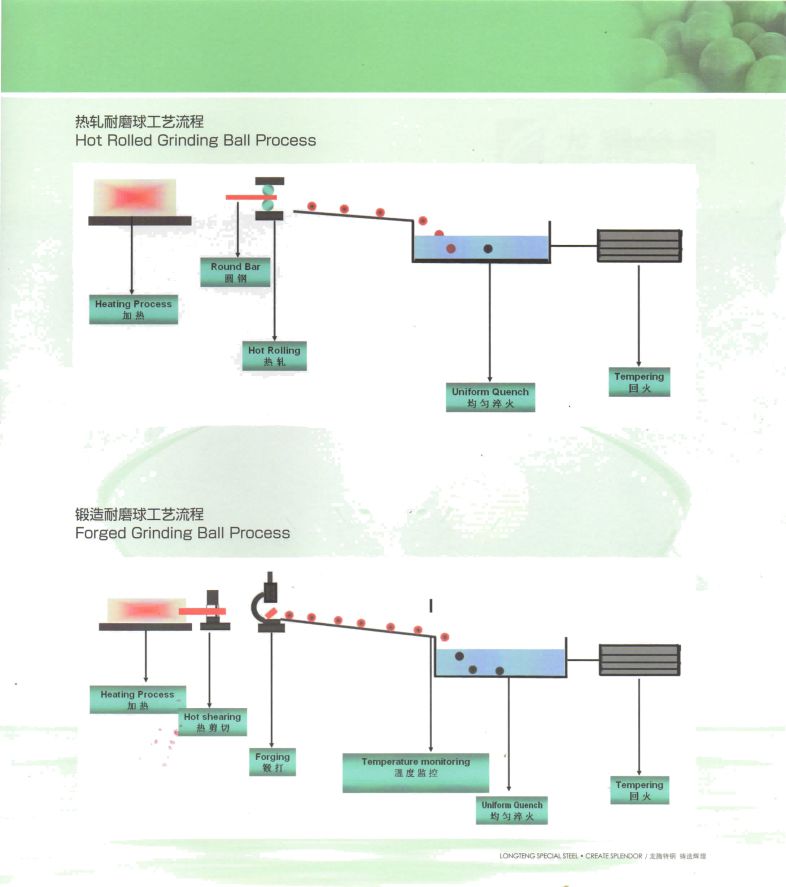

Wear-resistant steel balls for ball mills (referred to as wear-resistant balls) are widely used in large-scale gold mines, nickel ore, copper mines and other non-ferrous metal mines, iron ore and other ferrous metal mines, metallurgical and other precious metal beneficiation industries, used in ball mill crushed ore. . It has the characteristics of high hardness, low breaking rate and excellent wear, and is favored by users all over the world.

Specification

1. Roundness: The whole is spherical, with slight super saturation or unsaturated performance. Reference standard GB-8649-88 and YB/T 091-2005 2. Metallographic structure: a large amount of marten site structure, containing a small amount of retained austenite, binate and carbide 3. Breaking rate: No broken before shipping, Less than 1% under normal operating conditions

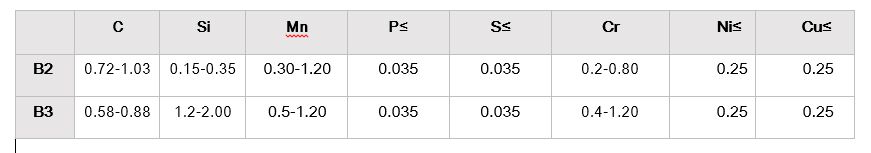

Chemical Composition